Lorem ipsum dolor sit amet, consectetur adipiscing elit. Curabitur bibendum, enim a imperdiet fermentum, libero urna consectetur leo, vel sagittis nunc velit ac nunc. Nulla sit amet dolor vel quam.

TECHNOLOGIES FOR ENVIRONMENTAL PROTECTION

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Curabitur bibendum, enim a imperdiet fermentum, libero urna consectetur leo, vel sagittis nunc velit ac nunc. Nulla sit amet dolor vel quam.

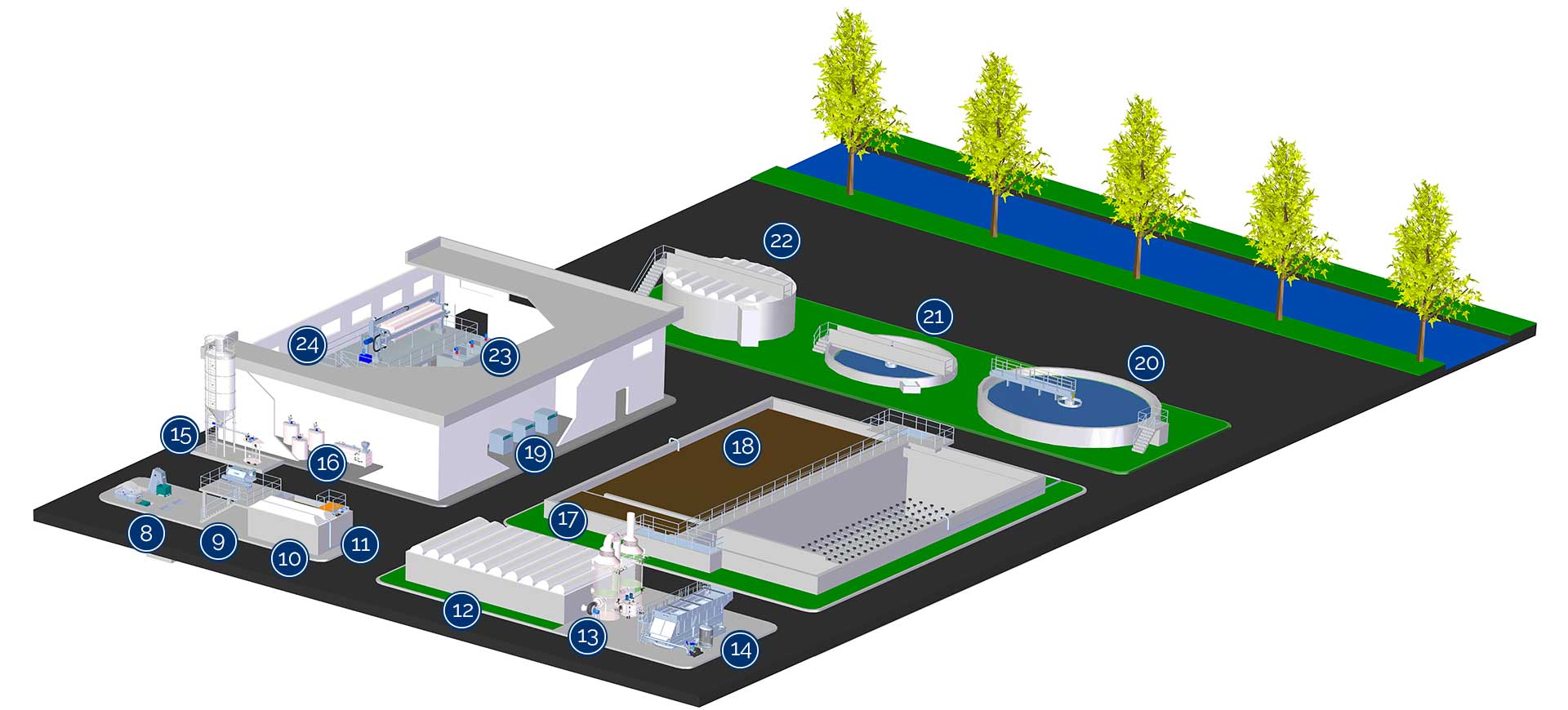

ITALPROGETTI makes available to our customers its know-how, gained for over 30 years in the tannery sector with the target to supply a robust and efficient solutions, reliable over time for the sulphides oxydation.

ITALPROGETTI design and realize preliminary tanks for grit and grease removal basin, for the management of tannery effluent with a high concentrations of inert and/or of flotable solids

Aerated/mixed basins for equalization and to homogenize are used to absorb the hydraulic peak flow and to homogenize the characteristics of waste water entering the treatment plant.The aeration systems provide to oxidize the residual sulphides concentration after the separate treatment of liming baths.

A correct design and correct management of a tannery waste water treatment plant can reduce at minimum the emissions of bad odors. For that reasons, ITALPROGETTI propose and realize odor collection system and deodorization units.

When the suspended solids concentration is very high o when it is requested to lower the pollutant load entering the biological treatment, it is possible to rise the efficiency of the spontaneous preliminary settling, by means of a chemical coagulation / flocculation of the suspended solids.

ITALPROGETTI desgin and realize automatic system for lime storage and for the preparation of lime milk, in order to minimize the manual activities in large effluent treatment plants.

The core of the plant is the biological treatment and ITALPROGETTI has developed different technologies to treat biologically tannery waste waters: conventional Activated Sludge system, MBBR technology (MovingBeds Biolofilm Reactor) and MBR treatment (Membrane Biological Reactor).

The biological reactors are equipped with air distribution systems with high efficiency diffusers, designed according to the biological technology adopted.

When among the standard parameters to respect there is Nitrogen too, besides the biological oxidation for the removal of the organic load, it is necessary a nitrification – denitrification treatment.

Nitrogen is first oxidized to Nitrates on an autotrophic biomass, that develops only in favourable condtions; Nitrates are then recirculated in a Denitrification basin, for their removal.

In anoxic conditions, that is without external supply of Oxygen, aerobic biomass uses the Oxygen of ion Nitrates for its activity, thus provoking the breaking of the Nitrate molecules and the release of harmless gaseous Nitrogen in atmosphere.

By means of this procedure, the high content of Nitrogen is definitively removed from the effluent.

Compressed air generation is a strategic part of biological treatment. Long term collaborations with major brands allows ITALPROGETTI to finely design the compressed air generation systems with the most efficient blowers for each type of application.

Air blowers room can be designed by Italprogetti with a dedicated insulation system in order to minimize the noise emissions.

A proprietary system for dissolved Oxygen control guarantees the minimum power consumption of blowers.

Tannery effluents are characterized by a high content of soluble -not biodegradabile organic load, which cannot be removed with a biological treatment.

When the final receptor of treated waters is surface water body (i.e. rivers) and the COD standard is very strict, it is necessary to install a final tertiary treatment for the removal of the refractory organic load.

Italprogetti proposes different technologies, according to the type of organic load to remove and to the capacity of the plant: granular activated carbon filters, chemical oxidation treatment (for example Fenton process) or specific treatment for the precipitation and the settling of tannins.

The sludge generated by the waste water treatment plant is collected in a thickening tank, where by gravity it increases its dry solids concentration.

Thickening tanks of medium-big size are equipped with scraping bridge, that provide to scrape the thickened sludge from the bottom and to convey it inside a central collection tray.

Before pumping the sludge to the mechanical dewatering, it is necessary to condition it chemically in order to increase its filtration properties.

Italprogetti designs and manufactures systems for sludge dewatering with recessed chambers filterpresses, by means it is possible to achieve dry solids concentration much higher than other technologies (like belt-presses or decanters).

Thanks to the long experience of Italprogetti in the field of tannery waste waters, it is proposed an automatic system for the control and the management of the filtration cycle, that allows to adjust the sludge flow rates according to the pressure of the filter. The duration of the cycle is thus optimized and the dry concentration of the dewatered sludge is maximized.