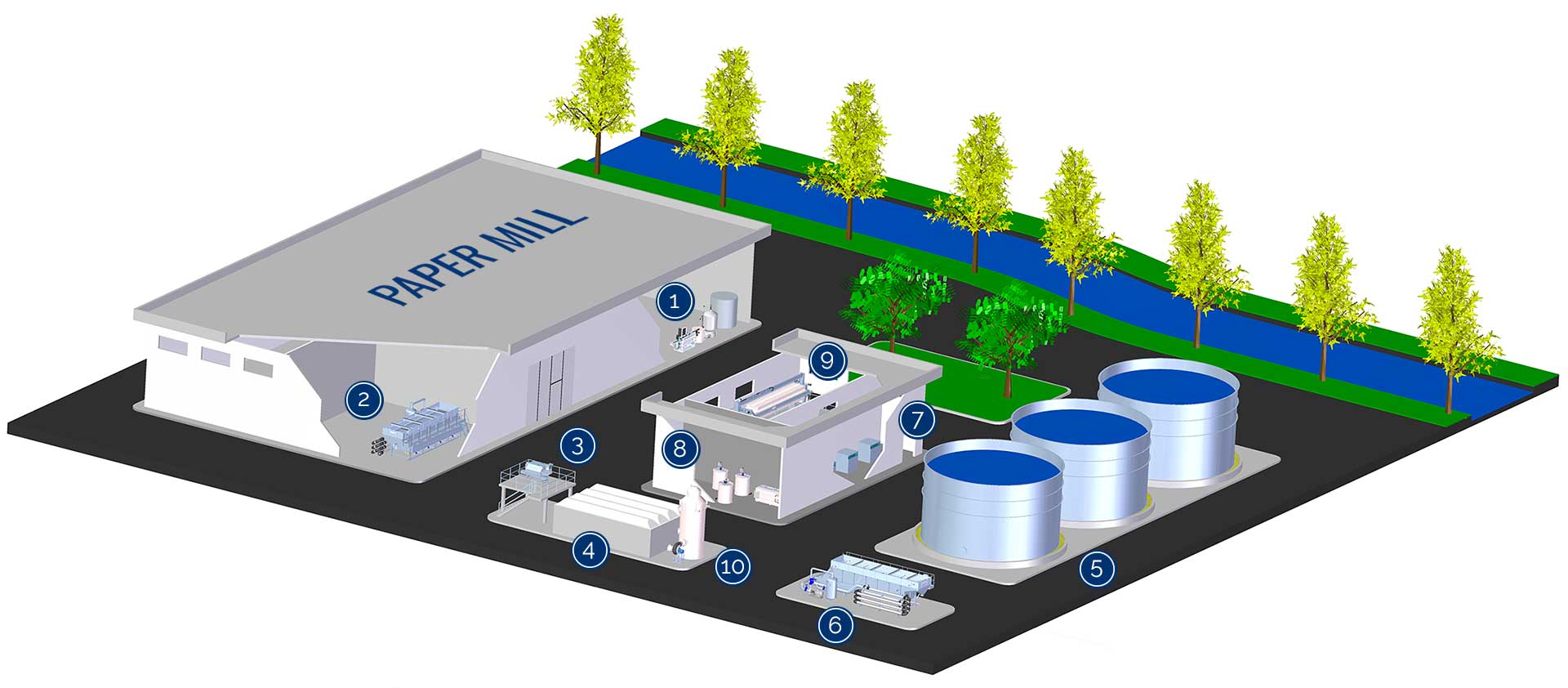

The freshwater treatment is an essential step in the paper mill process, ITALPROGETTI offers several solutions among the best available on the market .

FRESHWATER AND WASTEWATER TREATMENT PLANTS IN PAPER MILLS

ITALPROGETTI UltraCell DAF shows high efficiency in recovering the fiber of the paper mill’s internal water cycle. It guarantees a high flow rate with small dimensions and high efficiency in the removal of fibers.

ITALPROGETTI designs and manufactures two different screens for paper mills: the GSR and the KONICA.They allow to separate the fibers that are still present in wastewater after the flotation unit and before entering the treatment plant.

Aerated/mixed basins for equalization and to homogenize are used to absorb the hydraulic peak flow and to homogenize the characteristics of waste water entering the treatment plant.

The core of the plant is the biological treatment and ITALPROGETTI has developed different technologies to treat biologically paper mill waste waters: conventional Activated Sludge system, MBBR technology (MovingBeds Biolofilm Reactor) and MBR treatment (Membrane Biological Reactor).The biological reactors are equipped with air distribution systems with high efficiency diffusers, designed according to the biological technology adopted.

ITALPROGETTI UltraCell DAF represents the state of the art for final clarification of wastewater after biological treatment and it guarantees high standards of treated water before being discharge to the river (or other receptors).

Compressed air generation is a strategic part of biological treatment. Long term collaborations with major brands allows ITALPROGETTI to finely design the compressed air generation systems with the most efficient blowers for each type of application.Air blowers room can be designed by Italprogetti with a dedicated insulation system in order to minimize the noise emissions.A proprietary system for dissolved Oxygen control guarantees the minimum power consumption of blowers.

In order to boost efficiency of the treatment different chemicals can be used. Collaboration with major brands of product for water treatment allows ITALPROGETTI to propose the rigth solution for every treatment. Chemicals storage, preparation and dosage system is carefully designed to guarantee the maximum efficiency in usage of chemicals and maximum safety for the operators.

ITALPROGETTI may assist to recycle the sludge generated from ETP into the paper mill. When it is not possible, a dedicated sludge dewatering section is required. In this case we can offer sludge dewatering systems by filterpress, that guarantee the minimum water content in sludge on the market.

In most critical applications, where a strict control on odour emissions is requested, the treatment tanks must be equipped with coverings with a continuous air extraction and final treatment before emission to environment.Sucked air could be treated by wet vertical scrubber (where odors are absorbed in a aqueous chemical solution) or dry scrubber (where odors are adsorbed in a activated carbon bed).